If you take a closer look at the surfaces of processors and cooling system heatsinks, you’ll notice imperfections. These gaps trap air pockets that interfere with heat dissipation. That’s why thermal paste is applied to processors first — a viscous compound that fills all the surface irregularities and improves thermal conductivity.

In this article, we'll discuss which thermal paste to buy for your GPU and CPU, and why it's important to choose the right thermal interface for your system.

Why Choosing Thermal Paste Carefully Matters

The efficiency of heat transfer directly affects the operating temperatures of your components. The difference between cheap and high-quality thermal pastes can result in up to a 10°C temperature gap. That’s a significant margin that impacts the durability and stability of your computer hardware.

If you want to avoid thermal-related failures and extend the lifespan of your components, steer clear of low-quality thermal pastes like KPT-8.

Types of Thermal Interfaces

Most online stores don't have separate categories for thermal pastes. They’re usually listed under “thermal interfaces.” To help you make the right choice, let’s explore what thermal interfaces are and the different types available.

What Are Thermal Interfaces?

Thermal interfaces are any materials used to conduct heat: thermal pads, thermal adhesives, liquid metals, and more. Thermal pastes are one of the most common types. Let’s take a closer look at each one.

Liquid Metals

Liquid metals, like thermal pastes, are applied to both CPUs and GPUs. They offer the highest thermal conductivity and are considered the best thermal interface materials. However, they have several major drawbacks that prevent them from becoming mainstream:

- High cost. Liquid metals are about three times more expensive than thermal pastes. For example, 1 gram of Thermal Grizzly Aeronaut costs around 500 RUB, while the same amount of liquid metal can cost 1500 RUB.

- Electrical conductivity. If even a single drop of liquid metal contacts a live circuit on the motherboard, it may cause a short circuit — permanently damaging the board beyond repair.

- Difficult to remove. Liquid metals are hard to clean off heatsinks. Even special cleaning solutions sometimes fail, forcing engineers to use aggressive acids to remove residue.

- Difficult to apply. Liquid metals must be precisely applied to the processor’s center and evenly spread with cotton applicators. This takes significantly longer than applying regular thermal paste.

- Incompatibility with copper and aluminum heatsinks. Liquid metals react chemically with copper and aluminum alloys. They can only be used with nickel-plated heatsinks.

These drawbacks make liquid metals an unpopular choice. Engineers still rely on thermal pastes, which have proven to be far more reliable over many years in the computer industry.

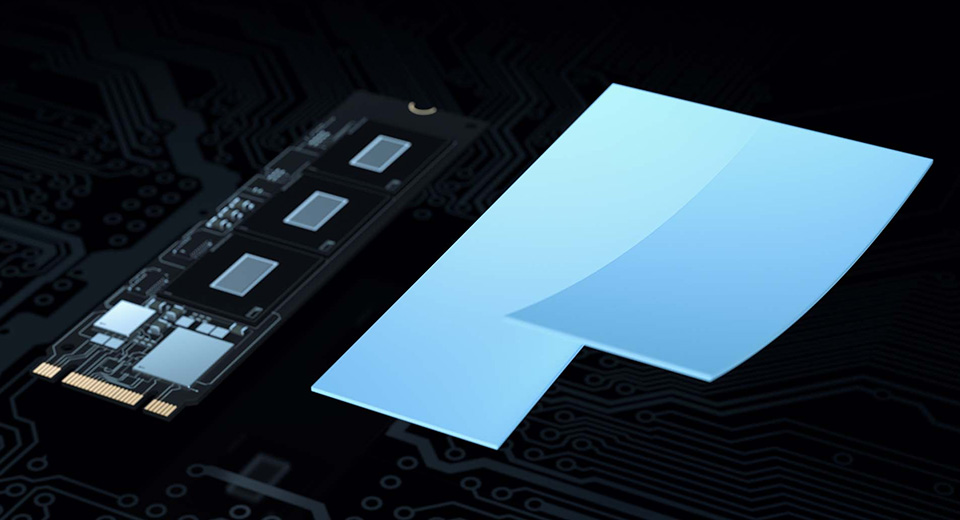

Thermal Pads

Thermal pads are used in areas where maximum cooling efficiency is not required — for example, in the VRM zones of motherboards and graphics cards. They are installed between power elements and metal heatsinks.

Thermal pads have two main advantages:

- Dielectric properties. They are non-conductive, so there’s no risk if they come into contact with live elements like motherboard or GPU traces.

- Flexibility. Pads easily deform to fill gaps and uneven surfaces. That’s why they’re often used in complex surface areas where components are placed at different heights — such as where video memory chips meet metal heatsinks.

Thermal pads should not be used for cooling CPUs or GPUs. Their thermal conductivity is significantly lower compared to pastes or liquid metals.

Thermal Adhesives

Thermal adhesives differ from pastes in that they remain pliable only for a short time after application. Then they harden into a solid bond strong enough to support the weight of metal heatsinks without additional mounting hardware.

The drawback is obvious: thermal adhesives create such a strong bond that disassembling components can be very difficult. Inexperienced engineers can easily damage components when removing cooling systems. That’s why thermal adhesives are rarely used in the PC industry. They’re only applied when bolts or other mounting mechanisms can't be used.

Should You Pay Attention to Specs in Descriptions?

Many people think the key indicator of thermal paste efficiency is its thermal conductivity coefficient — but that’s not entirely true. These specs don’t always reflect real-world temperature performance.

You also don’t need to worry about maximum or minimum operating temperature ranges. We use PCs in regular indoor environments — there's no exposure to extreme heat or cold, so these specs are mostly irrelevant.

What You Should Actually Look at When Choosing Thermal Paste

Focus only on real-world temperature results from benchmark reviews available online. From our experience, we recommend the following thermal pastes:

- Noctua NT-H2

- Arctic Cooling MX-4

- Thermal Grizzly Aeronaut

We've used these pastes ourselves, so we can confidently recommend them. They offer excellent thermal conductivity, proven in actual performance tests. These pastes can lower CPU temperatures by around 5°C compared to others.

Also note: Arctic Cooling MX-4 is frequently counterfeited. If you decide to buy it, check for a QR code on the packaging — it will help you verify authenticity on the manufacturer’s website.

Package Size

If you're not professionally servicing computers, avoid buying large jars of thermal paste. A small syringe containing 2–3 grams will likely be more than enough. Don’t buy thermal paste "for future use" — it dries out over time.

Ideally, the packaging should include a small plastic spatula. It makes applying the paste to the processor’s heat spreader much easier. But if you already have something similar at home, there's no need to pay extra for a new one.

Conclusion

Let’s quickly summarize:

- Thermal paste fills microscopic gaps between the processor and the cooling system. This improves heat transfer and extends the lifespan of the chips. Additionally, lower CPU temperatures mean quieter fan operation.

- When choosing thermal paste, focus only on real-world test results. There's no point in looking at thermal conductivity coefficients or max operating temperatures — actual performance is what matters.

- Don’t confuse thermal paste with other thermal interface materials like thermal adhesives, thermal pads, or liquid metals.

We’re often asked: “Which thermal paste should I choose for a laptop?” In reality, there’s no difference. All the recommendations in this article apply equally to laptops and desktop PCs.

Which Thermal Paste is Used in HYPERPC Computers

Reliability and longevity are core features of HYPERPC systems. We achieve this not only through high-quality components, powerful heatsinks, and well-ventilated cases, but also with premium thermal pastes like Noctua NT-H2 and Arctic Cooling MX-4. These compounds ensure optimal heat transfer and boost the effectiveness of our cooling solutions.